ТРАНСВЕСТ МОНГОЛИА ХХК

Бидэнтэй холбоо барих

Манай бүтээгдэхүүн үйлчилгээний талаарх дэлгэрэнгүй мэдээллийг бидэнтэй холбогдож авна уу!

Холбоо барих

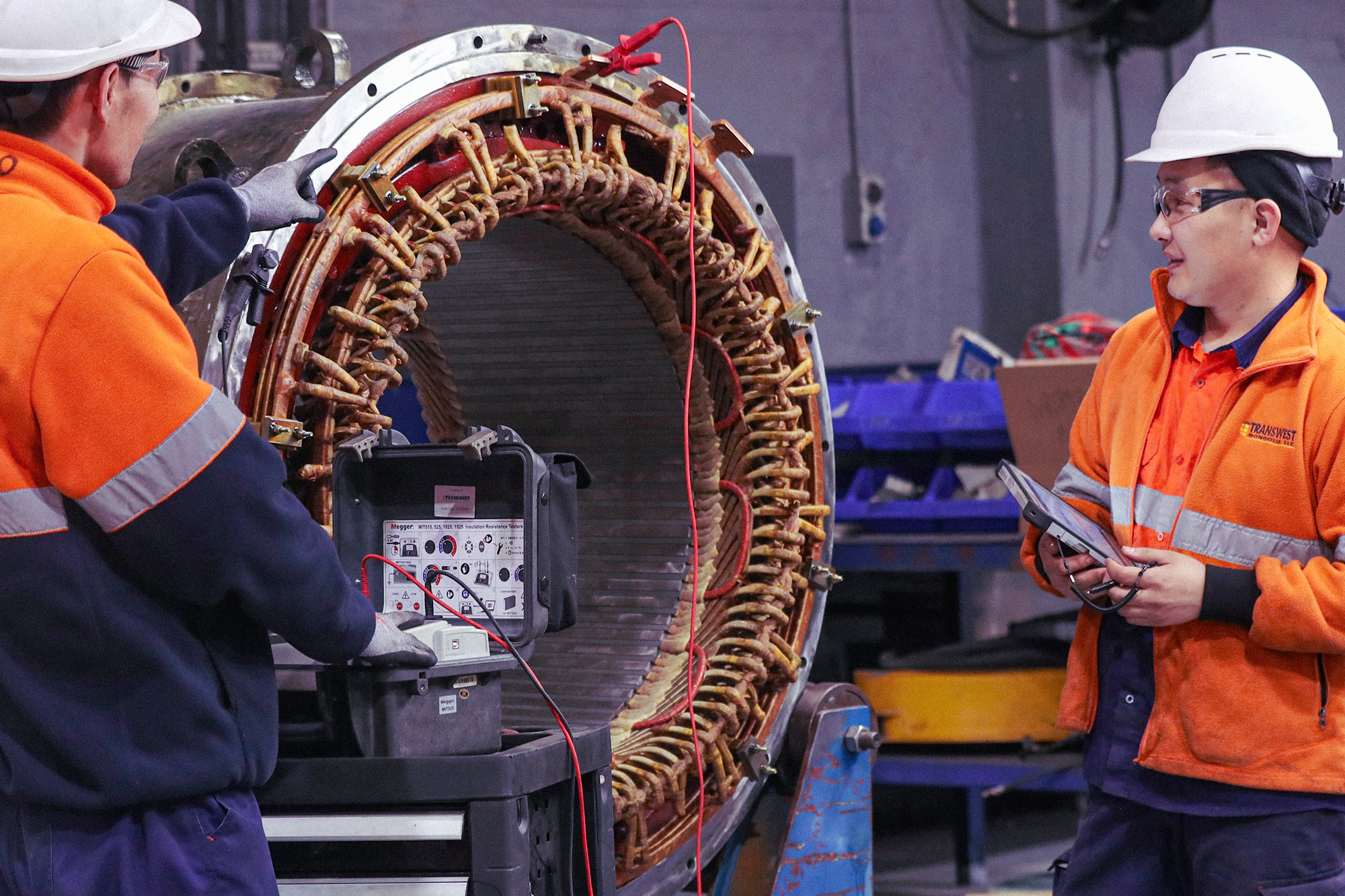

We offer a wide range of repair and rebuild options for various types of electrical components, especially motors and alternators for Komatsu and other manufacturers. Here is a description of the comprehensive rebuild process your component will undergo:

Манай бүтээгдэхүүн үйлчилгээний талаарх дэлгэрэнгүй мэдээллийг бидэнтэй холбогдож авна уу!

Холбоо барих